How to Choose the Right Air Dryer for Your Industry?

Why air dryers are critical for compressed air systems?

Industrial environments require diverse range of equipment for their functioning. Like electricity, fuel, water, and different types of oils; compressed air is also an essential need of many industries. Compressed air systems are essential for powering machines and power tools but to ensure their proper functioning air dryers are crucial to use. One of the major reasons is that air dryers are helpful in removing moisture from compressed air systems which helps prevent damage caused due to contamination, corrosion, and freezing. Considering their importance, it is advised to buy them from reputed Air Dryer Manufacturer only.

Use of right air dryers not only help remove moisture from these systems, but they also in keeping compressed air systems clean and dry. They ensure that industrial applications get clean and contaminant free compressed air. When used in cold environment, air dryers are helpful in preventing freezing of air inside pipelines, making them a convenient choice to support compressed air requirements. Let’s discover more about air dryers through this blog.

Types of air dryers (Refrigerated, Desiccant, Hybrid)

Considering the requirement of air dryers in multiple industries and to support several applications, there are different types of air dryers being designed to meet these applications. Some of the most common industrial air dryers supplied by us includes Refrigerated Air Dryers, Desiccant Air Dryers, and Hybrid Air Dryers.

Refrigerated Air Dryers

Among the diverse range of air dryers available in the market, refrigerated air dryers are considered the best. As the name suggests, they are used for cooling compressed air and helps in condensing moisture. Once it comes into the liquid form, it is then separated through drainage system and is dried away which is essential for preventing problems like microbial growth, corrosion, and freezing. The dew point of refrigerated air dryers is around 35 to 50 degree Fahrenheit. When buying from renowned air dryer manufacturer, one can easily get an energy-efficient and low maintenance air dryer for industrial use. Some of the industries where it is used includes manufacturing industry, food & beverage processing industry, pharmaceutical manufacturing industry, paint & coating applications and a few more.

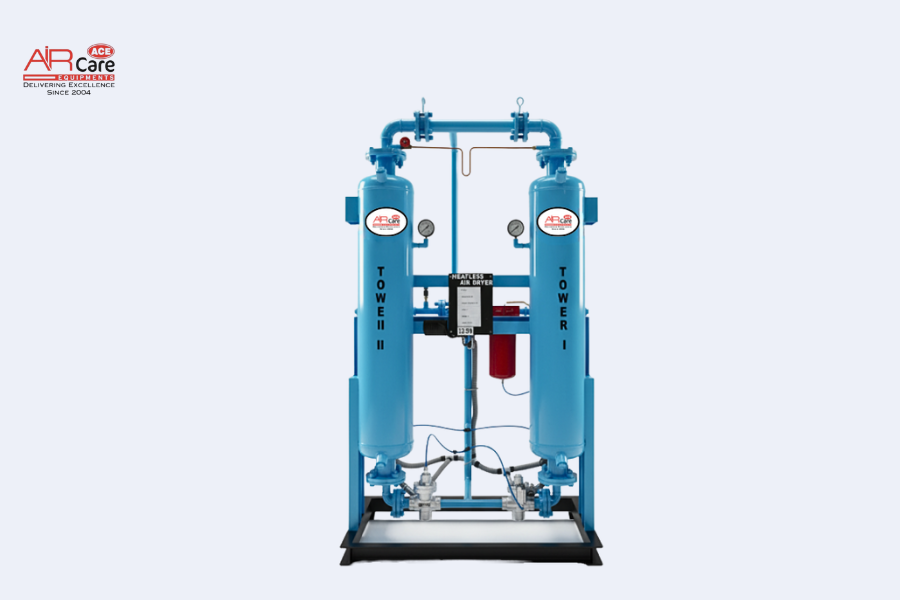

Desiccant Air Dryers

Desiccant air dryers are another widely used air dryers that use a chemical material which is also called desiccant for absorbing moisture. It comes in the form of activated alumina or silica gel and is helpful in removing water vapor from compressed air. Unlike the refrigerated air dryers which are not suitable for extremely low dew points, desiccant air dryers are suitable for low dew points as well which is what makes them a perfect choice for cold environments. These air dryers are suitable to use in pharmaceutical industry, electronics manufacturing industry, laser cutting industry, food processing industry, and a few more.

Hybrid Air Dryers

As the name says, Hybrid Air Dryers are a combination of both refrigerated and desiccant air dryers ensuring that they offer enhanced performance when it comes to removing moisture. In its initial stage, these air dryers make use of refrigerated dryer for removing moisture and later they may use of desiccant dryer so that they can dry air up to extremely low dew point. Considering the dual benefits offered by them, these are also known for their energy-efficiency. We at Air Care Equipment also customize these air dryers to meet multiple requirements shared by our customers from different industries to fulfil their moisture removal requirements. From manufacturing industry to food & beverage industry, pharmaceutical industry to plastic manufacturing industry, and a few more.

How to match air dryers to your industry?

Different industries have different compressed air requirements, especially when it comes to removal of moisture. According to their needs, the air dryer requirement also varies. Below, we are requirement of some industries where air dryer is used commonly.

Pharmaceutical Industry – In the pharmaceutical industry, maintaining cleanliness and hygiene is a must. Along with that one must also ensure that all the pharmacy products are free of contamination. As we all know that even trace amounts of moisture can lead to microbial growth or can compromise chemical formulations; so it is essential to use air dryers in this sector for removal of moisture. Desiccant Air Dryer is one of the most commonly used air dryers in the pharmaceutical sector. But it is advised that one must not compromise on its quality and should always buy from well-certified air dryer manufacturer.

Food Processing Industry – Food products packaging does require compressed air. Due to the direct contact of compressed air with food products, eliminating moisture content from compressed air is important, else it will lead to spoilage of food products, especially when they are required to be packed in air tight packaging free of moisture. Presence of moisture can develop mold or can contaminate food products and it may also alter the taste or color of food. It is one of the reasons why it is highly essential to ensure that the compressed air is completely dry and free of moisture. To obtain this, Hybrid Air Dryers are considered the best due to their dual technology. However, there are many places, where Desiccant Air Dryers are also used in food products packaging industry.

Packaging Industry – Unlike the pharmaceutical industry or food products packaging industry; packaging industry does not require ultra dry air. However, it still requires dry air to remove moisture content so that the products or equipment that are packed do not get damaged due to rust formation. It is also essential for smooth operation of pneumatic tools. In packaging industry, using Refrigerated Air Dryers is considered suitable to go for, unlike other industries we have mentioned above. The Refrigerated Air Dryer is sufficient to keep the air dry enough for packaging lines, especially if the packaging facility is climate controlled.

Mistakes to Avoid When Choosing an Air Dryer

When investing in air dryers, people often make several mistakes especially when they are unaware of the factors that one must consider when choosing an air dryer. Here, we are sharing some of those mistakes to help you avoid them when choosing the best quality air dryer.

- Not checking the air flow needs – Compressed air requirements at different industries vary and it is one of the reasons why it is advised to check the air flow needs before you invest in an air dryer. If the air dryer does not match with compressor’s capacity, it may cause pressure drop making air dryer function inappropriately.

- Buying one size air dryer for different industrial needs – As stated above, different industries require different air dryers depending on the requirement of compressed air, temperature, amount of moisture present in air, contaminants, and a few other factors. Considering the requirement and these factors, the size of air dryers also vary. So, one must not go for same size air dryer to meet all the requirements. Buying a size smaller may not meet all the compressed air requirements, whereas investing in a size larger may only increase power bills.

- Not buying energy-efficient air dryers – Industries where air dryers are used constantly to support compressed air system, often face the problem of high electricity bills. It mainly happens when one fails to check energy efficiency feature in air dryers. Ensure that you ask the manufacturer whether they are providing energy-efficient air dryers or not, else you will end up paying huge amount on electricity bills.

- Ignoring maintenance requirements – Every industrial equipment require maintenance and so does the air dryers. That is why, it is advised to check maintenance needs when buying air dryers. It will help you know how frequently it requires maintenance, the cost that goes into maintenance, and whether the air dryer manufacturers offer maintenance service or not.

Why Choose Air Care Equipment’s Air Dryers?

At Air Care Equipment, we understand that every industry has unique requirements and considering the same, we are manufacturing diverse range of air dryers to support them. From offering refrigerated air dryers to offering desiccant air dryers, we are known for fabricating all these air dryers with different configurations ensuring that they offer optimum performance for different compressed air systems.

Being one of the ISO approved air dryer manufacturer, we do not compromise with the industry standards and adhere to all compliances when manufacturing air dryers. We have engineered excellent quality air dryers which are considered best when it comes to removing moisture and contaminants from compressed air. We also customize air dryers according to the needs shared by different industries. Some of the industries to which we are supplying air dryers include pharmaceutical industry, food products packaging industry, manufacturing industry, packaging industry, and many more. All our air dryers are quality tested and are available with warranty and that too at affordable market prices.

FAQs about Air Dryers

- How frequently air dryers require maintenance?

Maintenance frequency of air dryers depends on the type of air dryer and its configuration. It also depends on the manufacturer you are buying from as high-quality air dryers do not require frequent maintenance whereas low quality air dryers may also require both maintenance and repairing. - Can we use a refrigerated air dryer in cold environments?

No, refrigerated air dryers are not considered ideal for cold environments. They are less effective in freezing conditions and are mainly suitable for environment with 35 to 50 degree Fahrenheit temperature. For cold environments, we recommend choosing desiccant dryers. - Why using air dryers is essential for compressed air systems?

Air dryers are crucial for compressed air systems, as they are responsible for eliminating any contaminants or moisture from the air which can affect the product quality or can even damage products completely. - What factors one should look for when choosing air dryers?

When investing in air dryers, one must check all these factors:

- Buy air dryers from certified manufacturers like Air Care Equipments

- Always invest in quality tested air dryers

- Check size and type of air dryer according to your compressed air system needs

- Go for energy-efficient air dryers

- Check maintenance needs and availability of warranty

Conclusion

Considering the benefits of air dryers for compressed air system, it is crucial to choose the right one by evaluating the air flow requirement. We at Air Care Equipment being one of the prominent air dryer manufacturers, we always maintain quality in all our air dryers and we do offer customization service to meet varying industrial needs. We are working with industry experts that ensure that we follow all the industry standards when manufacturing these. Whether you need air dryers for packaging industry or for food products packaging industry, we are there to offer durable and energy-efficient air dryers for all your needs.